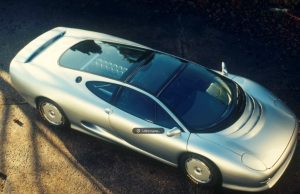

Jaguar XJ220: A leisure project

It was a group of Jaguar engineers and designers who developed this super sports car in their spare time. At the 1988 British International Motor Show in Birmingham, the result was unveiled to the public: a long, rounded ‘flounder’ quite unlike the then hyped Ferrari F40. Behind the cockpit of the XJ220 prototype sat a V12 engine powering all four wheels. Interest was huge when Jaguar boss John Egan announced a small series of 350 units, with many potential buyers expecting a significant investment. Ferrari and Porsche had already launched limited edition sports cars, such as the 288 GTO, the F40 and the 959, which became instant classics due to heavy media attention. As for the XJ220, 1,200 orders were placed despite the required deposit of GPB 50,000. One prospective buyer from Geneva even sent his cheque to Safenwil by taxi to be sure his reservation got there in time.

Factory visit

Jaguar handed over production to Tom Walkinshaw, who had just won the World Sportscar Championship twice for Jaguar. For series production, the engineers changed the heart of the prototype. Instead of the noisy V12 engine, there would be a V6 biturbo; and conventional rear-wheel drive would replace all-wheel drive, ensuring better weight distribution. The Jaguar Drivers’ Club Switzerland visited the production halls in Bloxham, England, in the summer of 1991. There they were able to admire the ultra-light, load-bearing XJ220 chassis, which consisted of two large longitudinal beams connected by the cabin floor, the rear wall of the cabin and a massive cross member at the front. The body material was manufactured from aluminium parts. On their factory visit, club members obtained pictures of the production process that were then published in the club magazine – not exactly to Jaguar’s delight.

Race car for the road

When test driver Andy Wallace tried out the production model in 1991, he reached a speed of almost 350 km/h, i.e. the 220 miles per hour referenced in its name – and a world record at the time. Wallace reported that on braking hard from a speed of over 320 km/h, the XJ220 still had the unbelievable directional stability of a race car. One year after the Swiss club’s visit to England, deliveries began. The purchase price rose to around CHF 1 million. In return, buyers received a 543 hp race car for the road that was rare, incredibly fast and elaborately handcrafted. In the end, however, only 281 cars left the Bloxham factory because the economy had cooled down and, along with it, the orders of many previously interested parties.

Knowledge transfer

Of the 80 or so Swiss XJ220 applicants, 21 were selected – which was a lot, considering that Jaguar only supplied 34 vehicles to Germany and three to Austria. Number 035 joined the Emil Frey collection as a new car. After some years on and off the road, it is finally undergoing a technical overhaul from Jaguar specialists Michel Tinguely and Guido Steigmeyer. Their many years of experience working for Jaguar in the Emil Frey Group have given them the expertise needed to maintain this race car for the road and passed on to our mechanics in the Emil Frey Classics workshop.

Pictures: Emil Frey Classics Archiv

What do our specialists say?

An interview with Michel Tinguely and Guido Steigmeyer

Former Jaguar Land Rover employees Guido Steigmeyer and Michel Tinguely completed their technical training on the Jaguar XJ220 over 32 years ago at JaguarSport in England. Today, they can be found overhauling the XJ220 from the Emil Frey collection and ensuring that their knowledge is preserved in the Emil Frey Classics workshop.

The experts: Michel Tinguely, Manuel de Gregorio and Guido Steigmeyer (from left)

How did the training go back then?

Guido Steigmeyer: We were able to study the parts directly during production so we had the best visual training material, and we took a lot of pictures and notes. Since the workshop manuals supplied afterwards were rather basic, personal experience was all the more important. Working on this car again today is an interesting and enjoyable challenge for us.

What’s so special about maintaining a Jaguar XJ220?

Guido Steigmeyer: It takes a long time to remove the entire drive unit. It looks easier than it actually is! Changing the timing belts is also a challenge. Particularly with vehicles that have not been driven for a long time, a service like this is a balancing act. What do you change and what do you keep? Of course, there is always the risk of old components failing after reassembly.

Michel Tinguely: After six years, you have to replace the plastic tank with its eleven foam rubber inserts or they will disintegrate. But the first challenge was to find a usable computer for the test programme on the diskette. Fortunately, Guido still had an old laptop with the necessary connections for the control unit. The task now is to secure this software and hardware for the future.

How is the spare parts supply for the XJ220?

Guido Steigmeyer: The supply of spare parts is basically good, with certain components such as the fuel tank even being reproduced. Fortunately, the matching Bridgestone tyres are also available again, though delivery times are sometimes long.

What is Emil Frey Classics doing to ensure the maintenance and repair of this supercar in the future?

Michel Tinguely: We will now be tackling a few more customer vehicles. The aim is for the Emil Frey Classics mechanics to learn from us and get all the specific know-how they need moving forward. It’s clear the team is highly motivated. We are also meticulously documenting all of the work steps to make sure this expertise is retained in the long term.